Forklifts are powered industrial trucks that save a lot of time and energy. They most commonly have a pronged device to lift and carry heavy loads. Developed in the 20th century, these monsters are dominating the workplace of many companies today. Whether they are needed to move heavy cargo on occasion or for huge projects for a long period, this vehicle has become go-to equipment We need to follow the forklift protocols for safety of our employees.

Forklifts are excellent pieces of workplace machinery, provided that you follow proper safety measures. They are often used in medium to large sites like warehouses, storage facilities, construction sites, and manufacturing sites.

After ensuring a forklift’s quality and durability, one should also check its safety. Maintaining safe habits around vehicles is a good first step. Maintenance is just as important as the type of the vehicles you are using. Giving enough time to check on these things can guarantee a safe workplace.

Forklift Protocols and Technology Advancement

Forklifts have changed drastically over the years. They are no longer huge diesel-powered machines. They now come in different shapes, sizes, weights, and even have specific uses. Transformed by the fast-paced growth of science and technology, they are more useful and flexible than ever, being specifically made for certain uses, places, and even environments.

Customization has also entered the forklift technology. Several parts can be attached for specialized use. Another noteworthy advancement in this field is the rise of electric forklifts. These vehicles also do not discharge emissions. This mitigates the company’s dependency on fossil fuel, enabling them to save money. This is just a few of the advancements in this field.

Forklift safety is for everyone’s benefit. ‘With great power comes great responsibility,’ as a common quote says. It is imperative for everyone who owns forklifts to be cautious when working with them. One wouldn’t want to have something so beneficial be harmful and destructive. The Occupational Safety and Health Administration (OSHA) estimates that more than 100,000 forklift accidents happen in the United States yearly. Despite the benefits that this technology provides, losses due to inherent hazards are still there. Because of the nature and weight of these trucks, accidents related to them tend to be very serious.

Things to Consider for Safe Forklift Use

Fatal injuries or even death are what lies beneath these big boys’ wheels. However, with knowledge, common sense, and by following safety protocols, all of these risks can be easily avoided.

Proper Maintenance and Repairs

It is essential not just for safety but also to ensure long service life. These big machines also cost big money, so you want to utilize these investments fully. You also want to reduce the chances of it breaking down. Checking the tires, air pressure and engine, and more is vital for the vehicle to handle the loads it will carry. Inspecting forklifts before and after use is important. It boosts the vehicles’ efficiency and the safety of operators and other workers.

Ensure Compliance With Laws and Regulations

Owning, leasing, hiring, or even borrowing a forklift comes with a huge responsibility. One should be aware of safety regulations that their municipality implements. In many cases, this type of vehicle is inspected first and eventually registered in order to be used legally. It is just crucial to be careful with this because of the huge risks these trucks carry. Aside from the paperwork, there are also safety forklift protocols that must be followed in many regions. However, they vary from state to state.

Employing Well-Trained Forklift Operators

A great forklift alone cannot do it all. It also needs a great driver. By hiring a certified forklift driver, the chances of having accidents that may result in injuries or even death will be reduced. An unlicensed driver not only risks workers’ safety, but the consequences of an accident can be quite expensive. Trained workers are already knowledgeable with safe work protocols such as wearing proper clothing, carrying out before-work checks, wearing operator restraints, reporting defects, and more. It also saves you the time and money it would cost to train them.

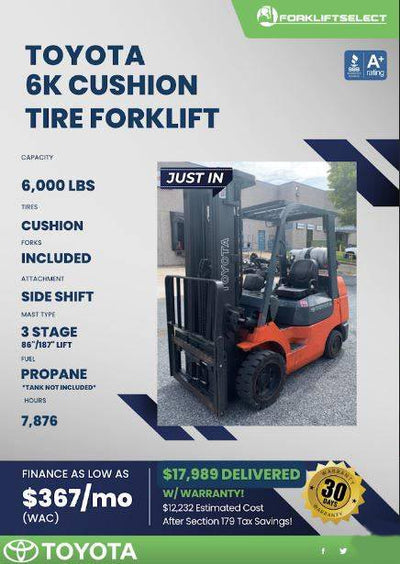

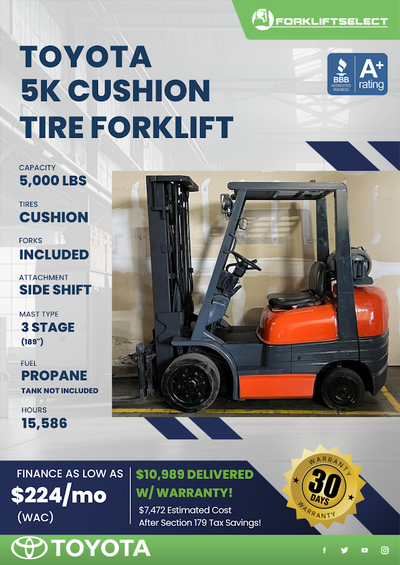

Forklift Select has every kind of lift you need. Whether it be big ones that can operate on rough terrain or smaller ones that can be used in your warehouse, we’ve got them all here! Browse through our website https://www.forkliftselect.com/ to learn more.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog