Food and beverage warehouses need forklifts that can keep products safe, clean, and moving fast. These spaces carry items that people eat and drink every day, so the equipment used inside must follow strict rules. This is why choosing the right forklift matters so much. The wrong machine can slow down work, damage goods, or fail inside cold or wet areas. The right one can improve safety, speed, and storage space. This is where Forklift Select in Denver, Colorado comes in. As a trusted local expert, the team helps businesses pick equipment that fits their needs. Forklift Select knows how important it is to match the right forklift with the right warehouse. When it comes to forklifts for food and beverage warehousing, there are key things every business in Denver and nearby areas like Aurora, Lakewood, and Commerce City should understand.

Understanding Forklift Needs in Food and Beverage Warehousing

Food and beverage warehouses work differently from regular storage spaces. These facilities handle items that stay fresh, clean, and safe. For this reason, the forklifts inside must be able to handle special conditions. Some products need cold rooms. Others need dry, clean aisles. Some items break easily. In every case, the forklift must help protect the product while still keeping work moving smoothly.

Many Denver food and beverage warehouses deal with mixed environments. This means one dock may be warm while another area is freezing. A forklift needs to handle both without slowing down. Warehouses also deal with different pallet sizes and stack heights. Forklifts used here must be able to lift high, fit into narrow aisles, and move safely around workers.

There are also cleanliness rules. Food-grade facilities must follow strict guidelines. Any forklift that enters these spaces must be easy to clean and made from safe materials. In Denver’s growing food production and distribution scene, having the right forklift setup makes a big difference for efficiency and safety.

Types of Forklifts Ideal for Food and Beverage Warehouses

Not all forklifts are built for food and beverage environments. Some work better in tight aisles. Others handle heavy pallets or frozen rooms. The best choice depends on the products, the warehouse layout, and the working temperature. Forklift Select helps Denver businesses choose the type that fits their workflow, storage setup, and safety needs.

Electric forklifts are one of the most common choices. They do not create fumes, which makes them safer for indoors food spaces. They are also very quiet. This helps workers hear each other and avoid accidents. Many Denver warehouses choose electric forklifts because they are clean and efficient. They work well in cooler or climate-controlled rooms too.

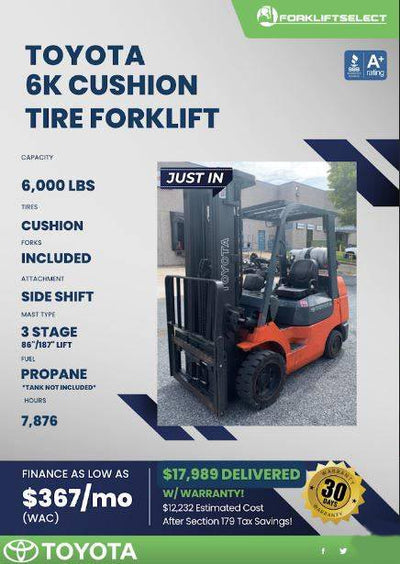

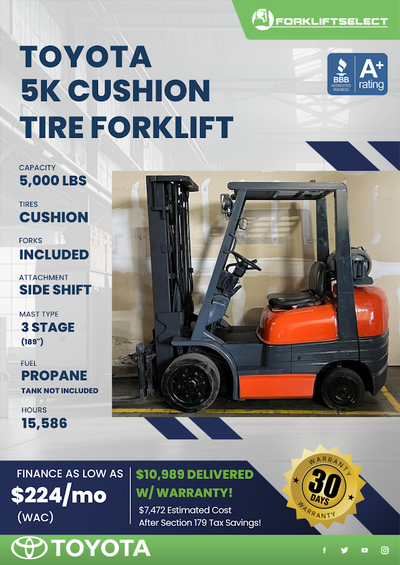

Propane forklifts can also be used, especially in loading areas or larger warehouses with strong ventilation. They offer power and strong lifting ability, which some beverage warehouses need for large or heavy pallets. Diesel forklifts are usually used outside or in yards. They are strong but not ideal indoors around food.

Reach trucks and narrow aisle forklifts are helpful in food storage areas where space is tight. These machines can lift high and move down slim aisles without hitting racks. Many beverage warehouses in Denver use reach trucks to place products on tall racks while still keeping the warehouse layout organized.

Specialty Forklifts for Cold Storage and Wet Environments

Cold storage warehouses need forklifts that can ruin in freezing temperatures without slowing down. Regular forklifts may struggle in icy environments. Batteries can drain faster. Tires may slip. Parts may freeze. Cold-storage forklifts are built with special seals, cold-rated hydraulics, and features that protect the machine. Food warehouses that handle frozen goods across Denver often choose forklifts designed for cold rooms so workers can keep moving without delays.

Wet or humid environments, such as beverage facilities where spills happen often, need forklifts with corrosion-resistant parts. Stainless steel forks, sealed electrical systems, and non-slip tires make a big difference in safety and durability.

Examples Uses in Denver Food and Beverage Warehouses

A local dairy warehouse in Denver might choose electric forklifts to keep aisles clean and quiet. A beverage distributor in Aurora might use propane forklifts in the loading area for fast unloading of heavy drink pallets. A frozen foods supplier in Commerce City may rely on cold storage forklifts that can handle temperatures far below zero. Every warehouse is different, but forklifts tailored to the environment help businesses move faster and work safer.

Sanitation and Compliance Considerations

Food and beverage warehouses must follow strict rules to keep products clean and safe. This also affects the type of forklifts used inside the building. A forklift that works in a food-grade space needs to be easy to clean. It should not have parts that trap dirt or bacteria. Smooth surfaces, sealed components, and rust-resistant materials are very important. Some forklifts even come with special coatings that help stop germs from spreading.

Forklifts in food areas must also follow OSHA and FDA standards. These rules protect workers and prevent contamination. For example, forklifts should not leak oil or fuel. They should not produce fumes that can touch food products. This is why electric forklifts are so common in Denver food warehouses. They are clean, quiet, and do not release harmful emissions.

Warehouse managers in cities like Denver, Aurora, and Lakewood also look for forklifts with easy-to-maintain designs. When cleaning is simple, workers spend less time on upkeep

And more time moving products. A forklift accident can damage goods or harm someone nearby. To avoid this, workers must receive proper training and understand how to operate the forklift in busy aisles.

Safety and Training Requirements

Safety is one of the biggest concerns in any warehouse, especially one that handles food and drinks. Products must be kept safe, but so do workers. A forklift accident can damage goods or harm someone nearby. To avoid this, workers must receive proper training and understand how to operate the forklift in busy aisles.

Forklifts built for food and beverage warehouses often include extra safety features. These may include warning lights, backup alarms, speed controls, and automatic braking. Some forklifts have sensors to help operators avoid obstacles. Others have stability systems that reduce the risk of tipping.

Food warehouses also deal with slippery floors. Spills from drinks, oils, or water can make aisles slick. Forklifts with non-slip tires and strong traction help keep workers safe. In cold storage areas, floors may freeze, so cold-rated tires are important. Training is key here. Operators must learn how to drive safely on wet or icy ground.

Many Denver-area businesses work with Forklift Select to make sure their operators use the right equipment for the right space. Training helps workers understand load limits, battery care, and speed control. When training and equipment work together, the entire warehouse becomes safer.

Optimizing Storage and Workflow with Forklifts

A good forklift can change the way a warehouse runs. Food and beverage facilities move products quickly. Items arrive, get stored, and leave again. Because of this, the layout of the warehouse needs to match the tools used inside it. Forklift Select often helps Denver businesses design better workflows using their forklifts.

For example, a narrow aisle forklift can save space. When aisles are slimmer, the warehouse can add more racks. More racks mean more products can be stored in the same building. This is helpful for food warehouses that deal with high inventory levels. Beverage warehouses often use reach trucks for tall racks because these forklifts lift high without taking up much floor space.

Attachments also help improve workflow. A rotating clamp attachment can handle barrels or large drink containers. A carton clamp can move boxes without using a pallet. Fork extensions help with long loads. These tools make the forklift more useful without needing extra machines.

Workflow Improvements in Different Warehouse Types

Dry food warehouses might use order pickers that help workers grab items from different rack levels. Beverage breweries or distributors may rely on high-capacity forklifts to move heavy pallets of drinks. A frozen food warehouse might need forklifts with heated cabins so workers stay comfortable in low temperatures. Each warehouse uses forklifts in its own way, but the goal is always the same: move products faster, safer, and with fewer steps.

Financing and Purchasing Considerations for Local Businesses

Buying or leasing a forklift is a big decision. Food and beverage warehouses often need multiple forklifts to stay productive. This can be a large investment. Forklift Select in Denver offers financing options that help companies get the equipment they need without slowing down their cash flow.

Leasing is a good option for businesses that want newer forklifts without paying the full cost upfront. It also allows companies to upgrade machines as their needs change. Buying is better for warehouses that want long-term ownership and plan to use the same equipment for many years. Forklift Select helps Denver warehouse managers compare their options and choose what fits their budget and workflow.

Another important factor is ROI. The right forklift can save money by reducing product damage, speeding up tasks, and lowering repair costs. Many Denver-area businesses find that choosing the correct forklift type and features leads to smoother operations and long-term savings.

Emerging Trends in Food and Beverage Warehousing Forklifts

The food and beverage industry is changing fast. Many warehouses today are adding smart technology to their forklifts. Some machines now have sensors that track battery health, load weight, and travel patterns. These features help managers predict when repairs are needed or find ways to improve workflow.

Energy-efficient forklifts are also becoming popular in Denver. Electric forklifts now last longer on a single charge and offer fast charging options. This helps warehouses keep moving without long downtime. There are also more eco-friendly models that reduce emissions and support green warehouse goals.

Automation is another big trend. Some warehouses use semi-automated forklifts or guided vehicles to handle simple tasks. While not every business is ready for full automation, many Denver warehouses are exploring smart tools that improve safety and speed.

FAQ Section

What type of forklift is best for refrigerated warehouses?

Electric forklifts with cold-rated parts are best because they work well in freezing temperatures and do not release fumes.

Can forklifts be used safely around food products?

Yes. Clean, well-maintained forklifts with sealed systems and no emissions are safe for food areas.

How often should forklifts be serviced in a food warehouse?

Most warehouses service their forklifts every 200 to 250 hours, but high-use environments may need more frequent checks.

Are electric forklifts better than propane for food and beverage operations?

In most indoor food spaces, electric forklifts are better because they are clean, quiet, and produce no emissions.

Partner with Denver’s Trusted Forklift Experts

Choosing the right forklift for a food and beverage warehouse is one of the most important decisions a business can make. The right machine keeps products safe, supports workers, and helps the warehouse run smoothly. Forklifts built for food areas need to be clean, strong, and able to work in tight or cold spaces. They should support safety, improve workflow, and follow all food-grade rules. With the right equipment, a warehouse can move faster and protect every item on the shelf.

If your business is in Denver or nearby areas and you want forklifts that match your food or beverage warehouse needs, Forklift Select is here to help. Their team can guide you through choosing, customizing, and financing the best equipment for your space. Contact Forklift Select today to get expert help and book your free quote.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog