Choosing the right forklift can make or break your operation’s productivity, safety, and efficiency. Whether you’re running a large-scale construction project or managing a busy warehouse in Denver, Colorado, the right forklift setup isn’t just about power—it’s about purpose. Forklifts might look similar, but their design, durability, and performance differ drastically depending on where they’re used. Construction sites demand rugged, high-clearance machines that can handle rough terrain and unpredictable conditions. Warehouses, on the other hand, prioritize precision, maneuverability, and compact design for tight indoor spaces.

At Forklift Select, we help businesses across Denver and nearby areas like Aurora, Lakewood, and Thornton find the perfect forklift for their specific needs. With a large inventory of new and used forklifts from trusted brands—plus flexible leasing and financing options—Forklift Select makes choosing the right equipment simple and cost-effective.

In this blog, we’ll break down the main differences between forklifts used in construction and those designed for warehouse environments, explore what makes each one unique, and help you decide which type fits your operation best.

Understanding the Basics: What Forklifts Are Built to Do

Forklifts are versatile material-handling machines built to lift, move, and transport heavy loads safely and efficiently. But not all forklifts are created equal. The environment in which they operate significantly affects their design and function.

Forklifts built for construction are designed to tackle rugged terrains, uneven ground, and heavy-duty lifting. They’re often equipped with pneumatic tires, reinforced masts, and powerful diesel or LPG engines that generate the torque needed for outdoor work.

Warehouse forklifts, in contrast, are built for controlled indoor environments. They feature compact frames, cushioned tires, and electric or battery-powered motors that minimize noise and emissions—ideal for tight aisles and long shifts.

Understanding these distinctions helps you identify what matters most for your job site—whether it’s stability on gravel or precision in narrow aisles.

Comparing Construction vs. Warehouse Forklifts

Construction and warehouse forklifts might share the same purpose—lifting and moving heavy materials—but the environments they operate in couldn’t be more different. Construction sites are unpredictable, filled with uneven surfaces, mud, debris, and constantly changing layouts. Forklifts in this setting need raw strength, durability, and stability. Pneumatic tire forklifts, for instance, are perfect for these conditions because their air-filled tires provide excellent traction and shock absorption. Rough-terrain forklifts are another popular choice, offering four-wheel drive, powerful engines, and high ground clearance to handle slopes and soft soil with ease.

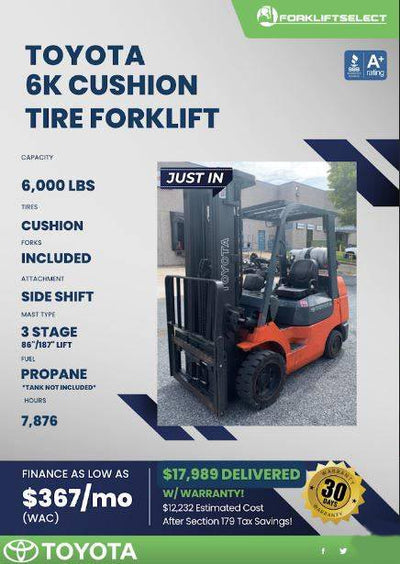

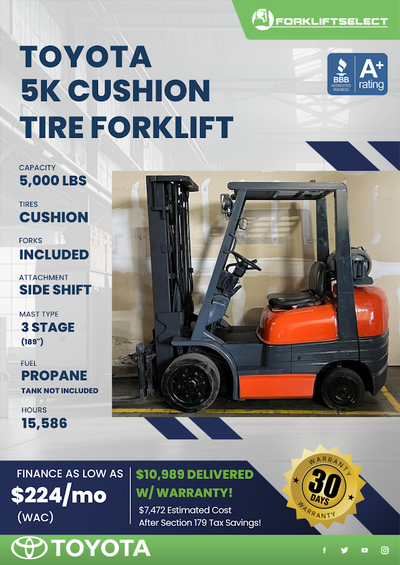

Warehouse forklifts, on the other hand, thrive in predictable, well-maintained indoor environments. Here, precision and control matter more than brute power. Cushion tire forklifts are a staple in warehouses because their solid rubber tires work best on smooth surfaces, allowing for tight turns and stable handling in narrow aisles. Electric-powered forklifts also dominate warehouse operations due to their quiet performance, zero emissions, and lower long-term maintenance costs.

Another key difference lies in load handling and visibility. Construction forklifts often lift heavier, irregularly shaped materials like pallets of bricks or steel beams, requiring robust hydraulic systems and strong masts. Warehouse forklifts, meanwhile, are optimized for consistent, repetitive tasks such as stacking pallets or retrieving items from racks at precise heights.

Ultimately, choosing between these two types of forklifts comes down to your environment and daily operations. If you’re working outdoors and dealing with rough surfaces, go for a rugged pneumatic or rough-terrain model. If you’re managing an indoor facility with tight aisles, a compact, electric-powered cushion tire forklift will offer the maneuverability and efficiency you need.

Construction Forklifts: Built for Power and Durability

Construction forklifts are engineered to withstand tough conditions and unpredictable terrain. They’re built like tanks—heavy-duty, high-torque, and designed to keep going even in mud, gravel, or uneven ground.

Key Features of Construction Forklifts

-

Rough Terrain Capability: Equipped with pneumatic or solid pneumatic tires that grip loose or uneven ground.

-

Higher Ground Clearance: Allows forklifts to move over obstacles commonly found on construction sites.

-

Powerful Engines: Typically diesel or LPG-powered for maximum torque and endurance.

-

Enhanced Load Capacity: Ideal for lifting heavy materials like concrete blocks, steel pipes, or lumber.

Construction forklifts also come with reinforced frames and weather-resistant components, ensuring they can handle both the workload and environmental elements. These forklifts often feature higher mast heights and longer fork lengths for handling oversized loads, making them indispensable in outdoor, high-intensity environments.

Best Forklift Types for Construction Sites

-

Rough Terrain Forklifts: Designed specifically for uneven surfaces and outdoor lifting tasks.

-

Telehandlers: Offer extended reach, allowing operators to lift materials to upper floors or elevated platforms.

-

Pneumatic Tire Forklifts: Provide superior traction and shock absorption for rough ground conditions.

If your projects often involve outdoor lifting, these forklift types will give you the stability, power, and endurance needed to maintain productivity without compromising safety.

Warehouse Forklifts: Designed for Precision and Efficiency

While construction forklifts thrive outdoors, warehouse forklifts are all about precision and control. Their smaller frames, tight turning radii, and electric drivetrains make them perfect for confined indoor spaces.

Key Features of Warehouse Forklifts

-

Compact Design: Ideal for narrow aisles and indoor storage facilities.

-

Electric Power: Reduces noise, emissions, and long-term operating costs.

-

Cushion Tires: Provide excellent stability on flat, smooth surfaces.

-

Operator Comfort: Many warehouse forklifts feature ergonomic seating and advanced controls to reduce fatigue.

Warehouse operations rely heavily on uptime and smooth transitions between tasks. Electric forklifts, for instance, have become increasingly popular due to their minimal maintenance needs and eco-friendly operation. Many models also offer regenerative braking, which extends battery life and enhances efficiency during long shifts.

Best Forklift Types for Warehouse Environments

-

Reach Trucks: Perfect for reaching high shelves and maximizing vertical space.

-

Order Pickers: Designed for quick and efficient item retrieval.

-

Counterbalance Forklifts: Versatile and well-suited for general warehouse duties.

The right warehouse forklift will depend on your layout, load types, and daily tasks—but choosing one designed for indoor use will always translate into smoother, safer operations.

Maintenance and Cost Considerations

Forklift ownership involves more than just the upfront purchase price. Long-term performance, maintenance, and energy costs can make a big difference depending on your choice.

Construction forklifts typically require more frequent maintenance because they operate in harsh environments that expose parts to dirt, dust, and debris. Diesel engines also need regular oil changes, air filter replacements, and inspections to keep them in optimal condition. However, their strength and reliability often justify the higher maintenance investment, especially for heavy-duty outdoor work.

Warehouse forklifts, particularly electric models, are generally cheaper to maintain over time. They have fewer moving parts, no engine oil, and minimal fluid requirements. Charging costs are significantly lower than refueling with diesel or LPG, and electric motors tend to have a longer lifespan when properly maintained.

In short, if your operation involves consistent, heavy outdoor lifting, expect higher maintenance costs. If you’re working indoors with repetitive handling tasks, electric warehouse forklifts can save you money and time in the long run.

Environmental Impact and Energy Efficiency

Sustainability is becoming a bigger factor in how businesses choose their equipment. In Denver and other eco-conscious cities, electric forklifts have surged in popularity due to their clean, quiet, and energy-efficient performance.

Electric forklifts produce zero emissions, making them ideal for indoor facilities and companies looking to reduce their carbon footprint. They’re also more energy-efficient, converting electricity into movement with minimal waste.

Diesel or LPG forklifts, often used in construction, offer raw power but come with higher emissions and noise levels. Still, they remain essential in outdoor environments where charging infrastructure isn’t available.

Ultimately, balancing performance needs with sustainability goals is key. Forklift Select helps customers find models that align with both productivity and environmental standards—whether that’s a rugged diesel machine for a construction site or a quiet electric model for an indoor facility.

Safety Differences Between Construction and Warehouse Forklifts

Safety is non-negotiable, but it looks different depending on where you operate. On construction sites, operators must contend with unstable surfaces, weather conditions, and unpredictable hazards. In warehouses, confined spaces and pedestrian traffic present different challenges.

Construction Forklift Safety Tips:

-

Always inspect tires, brakes, and hydraulics before use.

-

Maintain safe speeds and avoid sudden turns on uneven terrain.

-

Use spotters when visibility is limited.

-

Ensure loads are balanced and secure before lifting.

Warehouse Forklift Safety Tips:

-

Keep aisles clear and marked for safe navigation.

-

Train operators to manage tight turns and blind spots.

-

Perform daily battery checks and charge safely.

-

Follow designated travel paths to prevent collisions.

Both settings benefit from consistent operator training, daily inspections, and adherence to OSHA standards. A forklift is only as safe as its operator—and routine maintenance is key to keeping everyone protected.

FAQs: Choosing the Right Forklift

1. Can I use a construction forklift in a warehouse?

Not recommended. Construction forklifts are larger, heavier, and designed for uneven ground. Using one indoors can damage floors and reduce maneuverability.

2. Are electric forklifts powerful enough for outdoor use?

Electric forklifts can handle light outdoor tasks on smooth surfaces but aren’t ideal for rough terrain or heavy lifting in outdoor conditions.

3. What’s the most cost-effective forklift for long-term use?

Electric forklifts typically offer the lowest long-term costs due to minimal maintenance and lower energy expenses.

4. How often should forklifts be inspected?

Daily pre-shift inspections are crucial. Regular professional servicing every few months ensures safety and longevity.

5. Can Forklift Select help me choose the right model?

Absolutely. Forklift Select specializes in helping customers find forklifts suited to their exact operations, offering personalized guidance and flexible financing options.

Conclusion: Get the Right Forklift for Your Business with Forklift Select

Whether your work happens on a rugged construction site or a busy warehouse floor, choosing the right forklift can dramatically impact your efficiency, safety, and bottom line. Construction forklifts offer unmatched strength and stability for outdoor jobs, while warehouse forklifts provide the precision and control needed for indoor tasks.

At Forklift Select, we make the decision easy. With a massive inventory of new and used forklifts from major brands, expert advice, and flexible financing and leasing options, we’re Denver’s trusted source for all things forklifts. Serving the greater Denver area—including Aurora, Lakewood, Thornton, and Westminster—we’re ready to help you find the equipment that fits your business perfectly.

Call (877) 733-LIFT today to talk with a forklift specialist or explore our inventory online. Get the power, performance, and reliability your business deserves with Forklift Select.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog