Picture this: you’re in the middle of a busy shift, pallets are stacking up, deadlines are closing in and suddenly, your forklift stops working. Nothing kills productivity faster than an unexpected breakdown. It’s frustrating, costly, and often avoidable.

Regular inspections and maintenance can prevent most forklift issues before they turn into serious problems. At Forklift Select, we know how essential a reliable forklift is for your operations. That’s why we’re breaking down the top five most common forklift problems—and more importantly, how to fix them before they mess with your workflow.

1. Dead or Weak Battery

Ever tried to start your forklift and it just won’t budge? A dead battery is one of the most common forklift problems, especially for electric models. Here’s how to deal with it:

-

Check the battery charge – Make sure it’s properly charged before assuming there’s a bigger issue.

-

Inspect for corrosion – Buildup on the terminals can prevent proper charging.

-

Follow proper charging habits – Overcharging or undercharging can kill battery life faster than you think.

-

Replace old batteries – If the battery has reached the end of its lifespan, it’s time for a new one.

2. Forklift Won’t Start

If your forklift isn’t starting at all, don’t panic—there are a few things to check first:

-

Check the fuel level – Low or bad fuel can prevent ignition.

-

Inspect the ignition switch – A worn-out or faulty switch might be the problem.

-

Look at the starter motor – If it’s making clicking sounds but not turning over, the motor might need repair.

-

Test the battery connection – Loose or corroded cables can disrupt power flow.

3. Hydraulic Issues (Leaks, Weak Lifting Power)

If your forklift is struggling to lift loads or you notice fluid leaking, there’s a good chance you have a hydraulic problem. Here’s what to do:

-

Check for leaks – Look for fluid pooling under the forklift or dripping from hoses.

-

Inspect hydraulic fluid levels – Low fluid levels can lead to weak lifting power.

-

Examine hoses and seals – Cracks or worn-out seals can cause leaks and pressure loss.

-

Replace old or contaminated fluid – Dirty hydraulic fluid can damage the system over time.

4. Worn or Damaged Tires

Forklift tires take a beating daily, and bad tires can cause handling issues, increased fuel consumption, and even accidents. Here’s how to stay ahead of tire problems:

-

Check for visible wear – If the tread is gone, it’s time to replace them.

-

Look for uneven wear – This could indicate alignment issues.

-

Ensure proper inflation – Low pressure can affect performance and increase fuel costs.

-

Rotate tires regularly – This helps distribute wear evenly and extends their lifespan.

5. Faulty Brakes

Brakes are critical for forklift safety, so any signs of trouble should be addressed immediately. If your forklift is struggling to stop, here’s what to inspect:

-

Listen for unusual noises – Squeaking or grinding could mean the brake pads are worn out.

-

Check the brake fluid levels – Low levels can cause braking issues.

-

Test brake responsiveness – If the pedal feels soft or requires extra pressure, there’s likely a problem.

-

Schedule regular brake inspections – Preventative maintenance can keep small issues from becoming big (and expensive) problems.

How Forklift Inspections Save Money and Time

Catching these issues early not only keeps your operation running smoothly but also saves you money on costly emergency repairs. Regular inspections help:

-

Reduce downtime by fixing minor issues before they escalate.

-

Improve safety, preventing accidents caused by faulty equipment.

-

Extend the lifespan of your forklift, saving you from premature replacements.

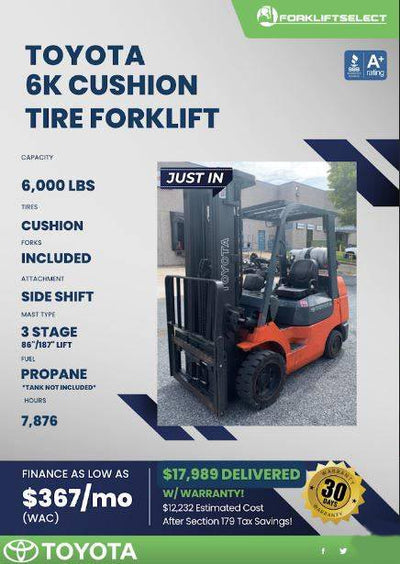

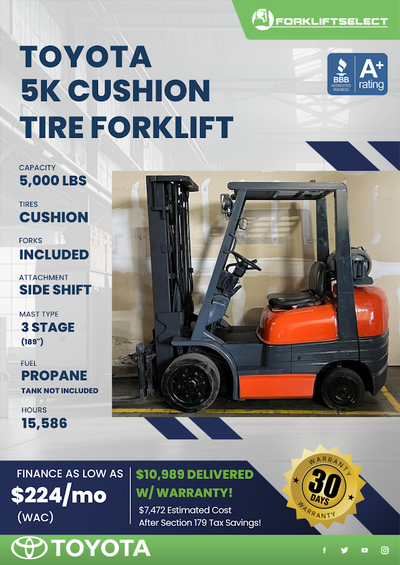

Forklift Select has a massive inventory of well-maintained new and used forklifts, ensuring you always have a reliable backup when you need it.

Regular forklift maintenance is the key to avoiding frustrating breakdowns and costly repairs. By keeping an eye on your battery, fuel, hydraulics, tires, and brakes, you can prevent most issues before they even start.

Need a forklift you can count on? Forklift Select has a wide selection of quality forklifts, both new and used, to keep your business moving.

Don’t let an unexpected breakdown slow you down! Call us at (719) 974-4744 or visit https://forkliftselect.com/ to find the perfect forklift for your needs.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog