Not all forklift batteries are built the same, and the choice between lithium-ion and lead-acid can make or break productivity in your warehouse. Lead-acid has been around forever—trusted, affordable, and still found in most forklifts today. Lithium-ion, on the other hand, is the newer player, gaining serious traction because of its efficiency and lower maintenance. Deciding between the two isn’t just about upfront cost. It’s about performance, safety, long-term value, and how much downtime your operation can afford. Let’s dive into what makes them different and which one might actually fit your business best.

The Basics: How Each Battery Type Works

Lead-acid batteries are the traditional go-to, and for good reason. They’re tried and tested, relatively inexpensive upfront, and reliable enough for many operations. The downside? They’re heavy, bulky, and require regular maintenance. Lithium-ion batteries, on the other hand, are modern tech in the forklift world. They’re lighter, charge faster, last longer, and require almost no maintenance at all. In simple terms, lead-acid is old-school but dependable, while lithium-ion is sleek, efficient, and built for performance-driven environments.

Performance & Productivity in Daily Use

This is where lithium-ion really starts to shine. Lead-acid batteries can take up to eight hours to fully charge, plus extra time to cool down, which means battery swaps and downtime are common in busy warehouses. Lithium-ion, by contrast, charges much faster and doesn’t require cooldown periods. Even better, it supports opportunity charging—you can plug it in during breaks or shift changes without damaging the battery. It also delivers consistent power throughout the shift, while lead-acid tends to lose steam as the charge runs low. In terms of pure productivity, lithium-ion keeps your operators moving while lead-acid lags behind.

Maintenance, Safety, and Longevity

Another big difference comes down to how much attention each battery demands. Lead-acid batteries need regular watering, proper ventilation during charging, and close monitoring to avoid leaks or acid spills. Lithium-ion doesn’t need any of that. It’s basically plug-and-play, which saves operators a lot of time and reduces workplace hazards. On the safety side, lithium-ion runs cooler and doesn’t release harmful gases, unlike lead-acid, which can pose risks if not handled properly. When it comes to lifespan, lithium-ion lasts two to three times longer—often 3,000 or more cycles—compared to the 1,000 to 1,500 cycles you’ll usually get out of lead-acid.

Cost Breakdown: Short-Term vs. Long-Term

Price is often the biggest deciding factor. Lead-acid batteries are cheaper upfront, making them an attractive choice for smaller businesses or operations that don’t push their forklifts too hard. The catch is the long-term costs. Factor in frequent replacements, maintenance time, and productivity losses, and lead-acid starts to look less appealing. Lithium-ion is definitely a bigger investment at the start, but because it lasts longer, requires less maintenance, and keeps downtime to a minimum, it usually pays for itself over time. Smaller operations may still lean toward lead-acid, but for high-demand, multi-shift warehouses, lithium-ion is often the smarter financial move.

Conclusion: Picking the Right Power for Your Fleet

So, which forklift battery is best? It really depends on your operation. Lead-acid batteries remain dependable for smaller warehouses or businesses on a tight budget, but if you’re running a high-volume, fast-paced operation where downtime is expensive, lithium-ion is the clear winner. It offers faster charging, longer lifespan, improved safety, and less hassle overall.

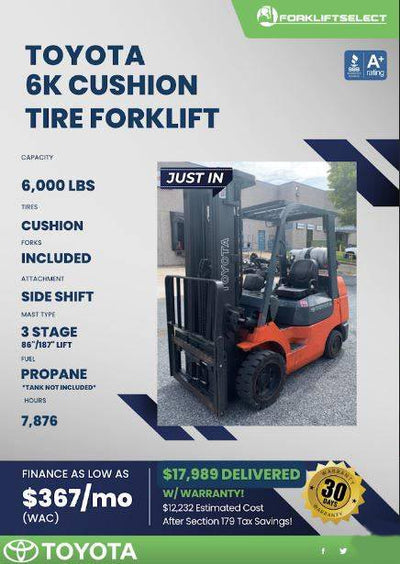

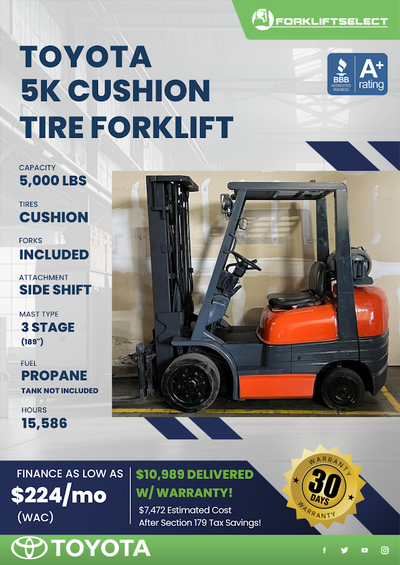

If you’re ready to level up your fleet—or simply want to weigh your options—Forklift Select has you covered. With one of the largest inventories of new and used forklifts from all the major brands, including reach trucks, order pickers, pallet jacks, and counterbalance trucks, you’ll find equipment that matches your business needs.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog