Envision a busy warehouse environment where forklifts operate continuously, workers manage demanding schedules, and operational efficiency is paramount. Such settings pose inherent safety risks, with the Occupational Safety and Health Administration (OSHA) reporting thousands of forklift-related injuries annually, ranging from damaged goods to severe accidents. Forklift cameras offer a transformative solution to mitigate these risks. Forklift Select, a trusted provider of new and used material handling equipment, including reach trucks, order pickers, pallet jacks, and counterbalance trucks from leading brands such as Toyota, Hyster, and Yale, has observed significant safety improvements among clients utilizing camera systems. This article explores how forklift cameras enhance workplace safety, improve operational efficiency, and reduce costly incidents, providing professional insights for businesses seeking to optimize their operations.

Why Forklift Cameras Are Essential for Safety

Forklift cameras are critical tools for enhancing visibility and reducing accidents in high-risk warehouse environments. Warehouses often feature blind spots, such as stacked pallets, narrow aisles, and active pedestrian zones. Cameras installed on forklifts, such as those compatible with Forklift Select’s diverse inventory, provide operators with real-time visibility of their surroundings. For instance, rear-view cameras facilitate safe navigation in crowded spaces, while mast-mounted cameras ensure precise load handling at heights, particularly for reach trucks operating up to 30 feet. According to OSHA, approximately 70% of forklift accidents could be prevented with improved visibility. By minimizing collisions and reducing damage to goods or injury to personnel, cameras are indispensable for maintaining a safe and efficient workplace.

Selecting the Appropriate Forklift Camera System

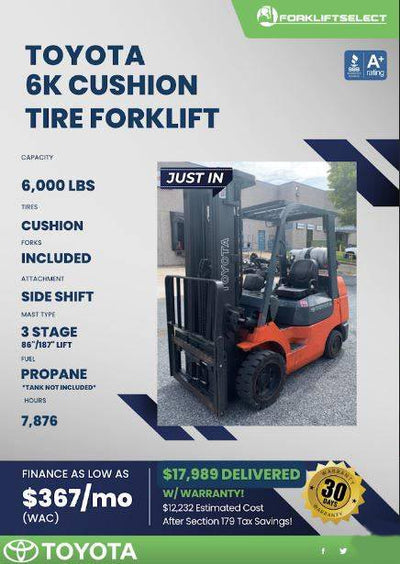

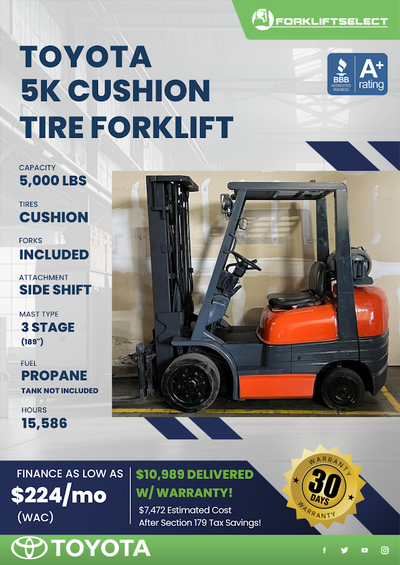

Choosing the right camera system requires careful consideration of operational needs. For outdoor operations using Forklift Select’s counterbalance trucks, such as the 2023 Patriot 8K Pneumatic Tire Forklift, a single rear-view camera may suffice. However, indoor environments utilizing reach trucks or order pickers benefit from advanced systems, such as 360-degree cameras or mast-mounted units for high-lift applications. Key features to consider include night vision for low-light conditions, waterproofing for outdoor durability, and compatibility with existing forklift controls. Wireless systems are often preferred for their ease of installation, particularly on used models like Forklift Select’s 2014 TCM 5K Cushion Tire Forklift. Forklift Select’s team of experts can assist in selecting camera systems tailored to specific equipment and operational requirements, ensuring seamless integration and optimal performance.

Training Personnel to Optimize Camera Utilization

The effectiveness of forklift cameras depends on proper operator training. Comprehensive training programs enable operators to leverage camera feeds for navigating challenging environments, such as narrow aisles with pallet jacks or high stacking with counterbalance trucks. Forklift Select’s clients have reported up to a 50% reduction in accidents when combining camera systems with structured training. Training should include practical exercises to build operator confidence in using live footage for decision-making, as well as routine camera maintenance checks to ensure clear visuals. Forklift Select provides resources to support training initiatives and can recommend camera systems compatible with its extensive range of forklifts, ensuring operators maximize safety and efficiency benefits.

Case Studies: Demonstrating Real-World Impact

The practical benefits of forklift cameras are evident in real-world applications. A Forklift Select client in Denver equipped their fleet of Yale order pickers with 360-degree camera systems, resulting in a 40% reduction in near-miss incidents within three months and a significant decrease in damaged goods. Another client, utilizing a 2019 Komatsu 3.5K Narrow Aisle Reach Truck from Forklift Select, implemented mast cameras and reduced load-dropping errors by 25%. These outcomes highlight the value of integrating camera systems with Forklift Select’s inventory, which ranges from cost-effective used forklifts to premium new models. Such investments enhance safety, reduce operational costs, and improve overall warehouse performance.

Conclusion

Forklift cameras are a vital investment for enhancing workplace safety, reducing accidents, and improving operational efficiency in material handling environments. By addressing visibility challenges, these systems protect personnel, equipment, and inventory, delivering measurable benefits for businesses. Forklift Select’s extensive inventory, including counterbalance trucks, reach trucks, and pallet jacks, pairs seamlessly with tailored camera solutions to meet diverse operational needs. To explore how forklift cameras can elevate your workplace safety, visit Forklift Select at https://forkliftselect.com/ or contact our team at (877) 733-LIFT or info@forkliftselect.com. We invite you to connect with our experts to identify the ideal equipment and camera systems for your organization, ensuring a safer and more efficient workplace.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog