If warehouses were video-game levels, each one would come with its own set of traps: razor-thin aisles, pothole-ridden loading docks, and arctic freezer rooms that make Hoth look toasty. Yet somehow forklifts keep rolling, stacking, and shuttling goods like it’s no big deal. Spoiler: it’s a huge deal—and it only works because smart engineers keep tweaking forklifts to survive whatever weird terrain we throw at them. Let’s break down how these metal workhorses shape-shift to match every warehouse mood swing.

1. Squeezing Through Tight Aisles & High Racks

Think of modern reach trucks as the parkour athletes of material handling. Their masts extend forward instead of forcing the whole truck to nose-dive into the rack, so operators can snatch a pallet from the top shelf without doing a 47-point turn.

-

Articulated steering: The chassis literally hinges in the middle, so the back end doesn’t need a football field to pivot.

-

Slim profiles: Safety cages trimmed just enough to clear low mezzanines—no more “clang” soundtrack echoing through the warehouse.

-

Height-sensing tech: Auto-slowdown when you’re near max extension; one less thing for the operator to sweat over.

Bottom line: More racks in the same square footage = fewer real-estate headaches and happier accountants.

2. Rolling Over Rough or Uneven Floors

Not every facility has billiard-table concrete. Loading docks collect cracked slabs, dock-level gaps, and the occasional rogue bolt.

-

Pneumatic tires: Air-filled, chunky tread that eats debris for breakfast and shrugs off curb ramps.

-

Beefed-up suspension: Keeps the driver’s spine intact and the load steady—because no one wants confetti boxes.

-

High ground clearance: Lets you cruise over hazards instead of high-centering like a beached whale.

Why it matters: Smoother rides mean less product damage, fewer maintenance calls, and operators who don’t feel 90 years old after a shift.

3. Beating the Chill in Cold Storage

Freezers aren’t just cold—they’re gear killers. Rubber seals turn rock-hard, oil thickens, and batteries wave the white flag.

-

Cold-rated hydraulics & seals: Stay flexible so cylinders don’t groan like rusty doors.

-

Heated battery packs: Maintain voltage instead of dying faster than your phone on 1%.

-

Corrosion-proof stainless hardware: Fights off the sweat/condensation cycle whenever the truck exits the chill zone.

Result? Your frozen pizza stays frozen, downtime plummets, and nobody has to MacGyver a forklift with a space heater.

4. Keeping the Air Breathable Indoors

You can’t slap a tailpipe belching fumes next to a salad-packing line—or employees who like breathing.

-

Electric drivetrains: Zero emissions, whisper-quiet, and—bonus—instant torque.

-

Lithium-ion batteries: Fast charging, no watering schedules, and longer duty cycles.

-

Regen braking: Captures energy on descents and deceleration, boosting runtime while shaving power bills.

Healthier lungs, happier safety auditors, and an ESG report that reads like a humble-brag.

5. Going Hybrid for Mixed-Use Facilities

Some sites juggle indoor racking, outdoor yards, and sketchy gravel lots all in one shift.

-

Dual-fuel or hybrid engines: LPG or diesel muscle outside; electric assist keeps indoor emissions nil.

-

Adaptive traction control: Sensors detect surface slip and tweak wheel speed before you fishtail into inventory.

-

Modular attachments: Quick-swap clamps, push/pulls, or carpet booms so one truck can wear many hats.

Fleet managers call it “utilization.” Operators call it “less walking.” Everyone wins.

Conclusion – Grab the Right Rig & Crush Your Conditions

Warehouses come in more flavors than energy drinks, and a one-size-fits-all forklift will let you down when the environment changes. The fix? Pick the machine that’s purpose-built for your daily chaos.

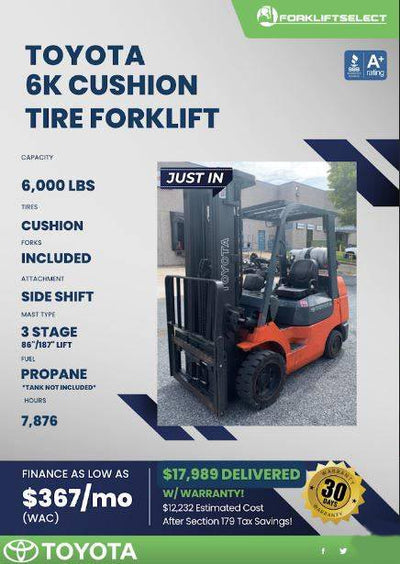

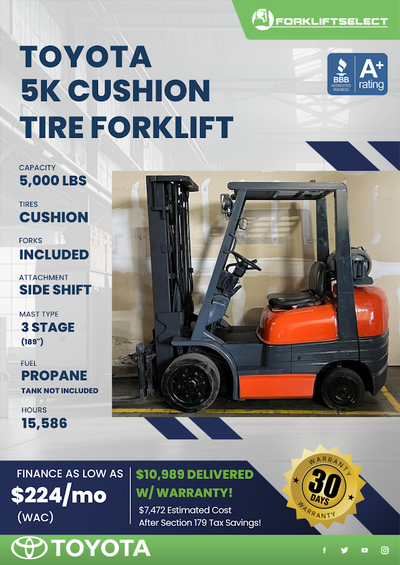

Forklift Select stocks a monster lineup of new and used reach trucks, pneumatics, order pickers, pallet jacks—you name it—from every big brand in the game. Our team nerds out on specs so you don’t have to.

🚀 Ready to level-up your fleet? Browse today, book a test drive, or hit us up for free advice. Let’s gear up your warehouse to smash whatever challenges tomorrow brings!

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog