Effective forklift fleet management can be a game-changer for businesses looking to control expenses and improve operational efficiency. From maintenance planning to equipment selection, implementing cost-saving strategies in fleet management helps businesses maximize productivity while minimizing overhead. Let’s explore key strategies that can help you reduce costs without compromising performance.

Top Strategies for Fleet Cost Savings

Implementing these forklift fleet management strategies can lead to significant savings:

- Routine Maintenance Plans: Schedule regular maintenance to avoid costly breakdowns and extend the life of your forklifts.

- Energy-Efficient Models: Consider using electric or hybrid models to save on fuel costs and reduce environmental impact.

- Utilize Data Tracking: Use telematics and tracking software to monitor forklift performance, enabling timely interventions and optimized usage.

- Operator Training Programs: Invest in training to improve operator efficiency and reduce wear on equipment, extending the life of each forklift.

- Lease Instead of Buy: Leasing allows for flexibility and lower upfront costs, making it easier to scale your fleet based on current needs.

- Standardize Parts and Models: Standardizing equipment can reduce the variety of parts needed for repairs, lowering maintenance costs.

How Forklift Select Can Support Your Fleet Management Needs

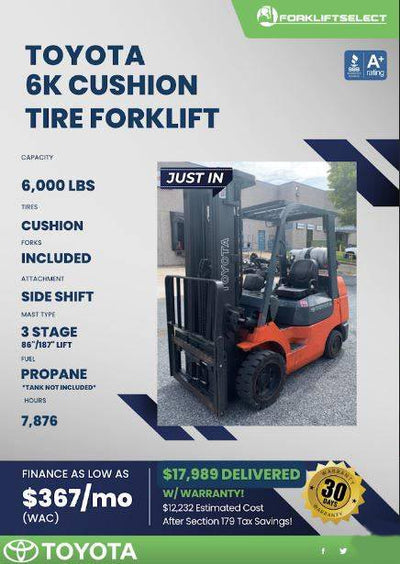

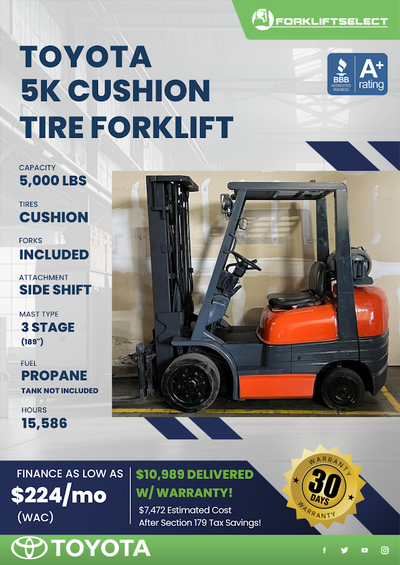

Forklift Select offers a large selection of new and used forklifts from leading brands, including specialized models like reach trucks, order pickers, and pallet jacks. Our inventory gives you the flexibility to select equipment tailored to your operational demands, ensuring that you’re investing in forklifts that boost productivity and align with cost-saving goals.

Get in touch with Forklift Select today to explore fleet management solutions that save you money and improve your operation. Call us at (877) 733 - LIFT or visit https://forkliftselect.com/ to learn more!

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog