Training forklift operators isn’t just a checkbox item for compliance—it’s the real-world key to safer, more efficient warehouses. Anyone can hop on a machine and move a pallet, but doing it without damaging products, burning time, or risking lives? That takes proper training. Whether you’re onboarding new hires or fine-tuning a veteran crew, forklift training should balance practical skills and safety protocols to get the best performance out of both your team and your machines.

1. Start with the Basics: Certification and Compliance

Before anything else, every forklift operator needs to be certified. In most regions, OSHA (or a local equivalent) mandates this, and skipping it isn’t just risky—it’s illegal. A solid training program should start here:

-

Classroom Instruction – Teach the theory: load capacities, types of forklifts, hazard awareness.

-

Hands-On Training – Let them operate under supervision in controlled conditions.

-

Evaluation – Test knowledge and skills before cutting them loose on the warehouse floor.

Certified operators don’t just tick a legal box—they also reduce liability and improve efficiency by knowing exactly how to work the machine safely and effectively.

2. Go Beyond the Manual: Real-World Application

Forklifts don’t operate in a vacuum. Every warehouse is different, and training should reflect that. Once an operator knows the basics, train them for your specific environment:

-

Layout Orientation – Where are the loading docks? High-traffic zones? Narrow aisles?

-

Load Types – Are they moving pallets, crates, or fragile equipment? Each requires different handling.

-

Equipment Familiarity – Not all forklifts are the same. From order pickers to counterbalance trucks, operators should know the quirks of each model.

This is where experience meets practice. Familiarity with both the facility and the equipment reduces accidents, increases speed, and builds operator confidence.

3. Build Safe Habits Through Daily Practice

Efficiency is great, but not at the cost of safety. Good habits form over time with consistent reinforcement. Make sure your operators follow protocols daily—not just during training week.

-

Pre-Operation Checks – Teach them to inspect brakes, forks, tires, and fluids before use.

-

Safe Driving Techniques – Enforce speed limits, turning rules, and proper load handling.

-

Communication Skills – Whether it’s hand signals or radios, operators need to be in sync with the team.

-

Parking & Shutdown Procedures – No one should leave a forklift with the forks raised or the key in the ignition.

The best operators don’t take shortcuts—they make the correct action a reflex.

4. Keep Skills Sharp: Retraining and Evaluations

Training isn’t a one-and-done deal. Forklift operation needs occasional refreshers, especially when:

-

New equipment is introduced

-

Layout changes affect workflow

-

An incident occurs

-

An operator’s performance starts slipping

Set up regular evaluations and offer short retraining sessions to keep everyone sharp. A quarterly or biannual review can do wonders for reinforcing skills and maintaining a safe culture.

Conclusion: Train Smarter, Work Safer

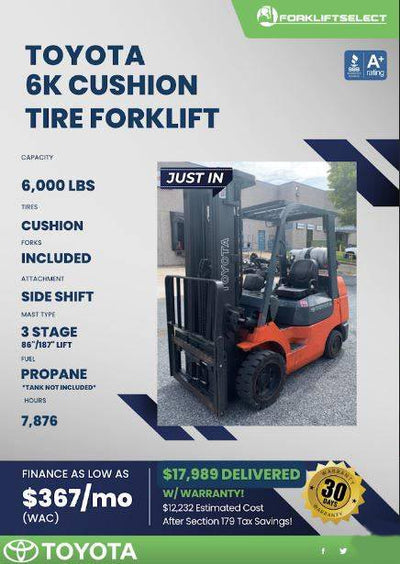

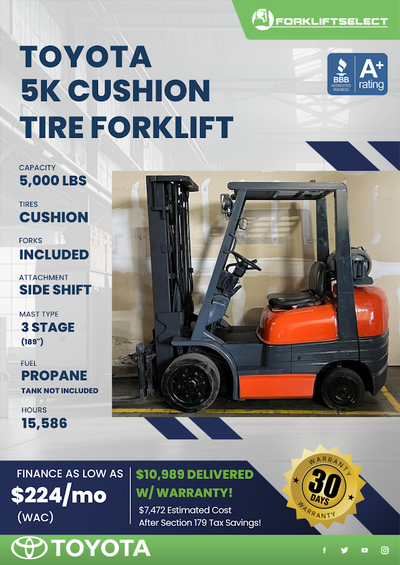

Training your forklift operators the right way pays off in reduced downtime, fewer accidents, and smoother workflows. Whether you're running a massive warehouse or a smaller logistics crew, investing in proper training practices is non-negotiable. And when your team is ready to take the wheel, Forklift Select has your back. With a wide selection of new and used forklifts—from pallet jacks to reach trucks—you’ll find the right equipment for every skill level and application.

🚜 Start training smarter. Check out Forklift Select’s inventory today!

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog