Forklift inspections are a lifesaver, especially in times when you’re in the middle of a busy day, orders are piling up, and suddenly, your forklift decides it’s had enough. Now you’re stuck, operations are at a standstill, and you’re scrambling to figure out what went wrong.

Forklifts are the workhorses of many industries, but they’re often taken for granted until something goes wrong. Routine inspections are like giving your forklift a regular health check—it keeps things running smoothly, avoids nasty surprises, and saves you a ton of stress. At Forklift Select, we pride ourselves on offering reliable new and used forklifts that are already a step ahead in quality, ensuring your operations stay on track.

Why Regular Inspections Matter

Forklifts play a crucial role in keeping your operations efficient, but skipping maintenance can turn them into liabilities. Here’s why inspections should always be on your radar:

-

Safety First: Regular checks help identify potential hazards, like faulty brakes or worn-out tires, before they become accidents waiting to happen.

-

Avoid Costly Repairs: A small issue caught early can save you from massive repair bills down the line.

-

Keep Things Moving: Downtime disrupts productivity. Inspections ensure your forklifts are always ready to go when you need them.

-

Prolong Lifespan: Taking care of your forklift means it’ll take care of you for longer, delaying the need for costly replacements.

Key Areas to Inspect for Optimal Performance

Not sure what to look for during a forklift inspection? Don’t worry; here’s a quick guide to the essentials. Checking these areas can help you stay ahead of the game:

-

Tires and Brakes: Keep an eye out for wear and tear. Bald tires and squeaky brakes are more than annoying—they’re safety risks.

-

Hydraulics: Look for leaks or sluggish operation. Smooth hydraulics are a must for efficient lifting and moving.

-

Engine and Battery: Check that the engine runs smoothly and the battery holds a charge. These are the heart of your forklift, and they need to be in top shape.

By giving attention to these components, you’ll significantly reduce the chances of unexpected downtime that can throw a wrench in your day.

How Forklift Inspections Save Money and Time

Think of inspections as an investment that pays off big time. Here’s how:

-

Catch Problems Early: A minor issue detected during a routine check is much cheaper to fix than a major breakdown.

-

Boost Productivity: Downtime is the enemy of efficiency. Regular inspections mean fewer interruptions and smoother workflows.

-

Be Deadline-Friendly: When your forklifts are reliable, you’re less likely to miss critical deadlines, keeping clients happy.

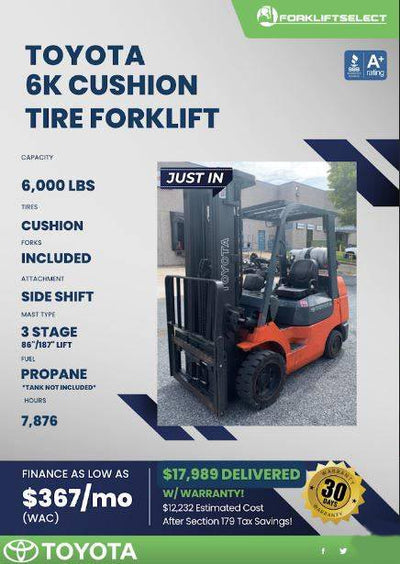

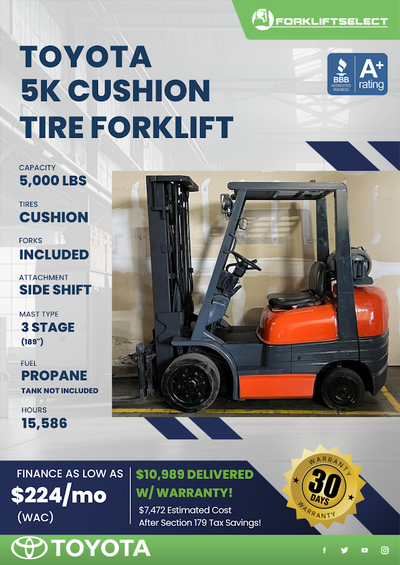

At Forklift Select, we make it even easier. Our inventory includes well-maintained used forklifts that are inspected and ready to tackle your toughest jobs. Need a backup while yours is under maintenance? We’ve got you covered.

Conclusion: Downtime No More

Taking a proactive approach to forklift maintenance is really smart and essential. Regular inspections keep your team safe, your operations efficient, and your costs under control. Whether it’s checking the brakes or ensuring the hydraulics are leak-free, these small steps make a big difference.

Ready to keep your operations running like a well-oiled machine? Forklift Select offers an extensive inventory of new and used forklifts that deliver performance you can count on.

Don’t let an unexpected breakdown slow you down! Call us at (877) 733 - LIFT or visit https://forkliftselect.com/ to find the perfect forklift for your needs.

(877) 733 - LIFT

(877) 733 - LIFT

Back to blog

Back to blog